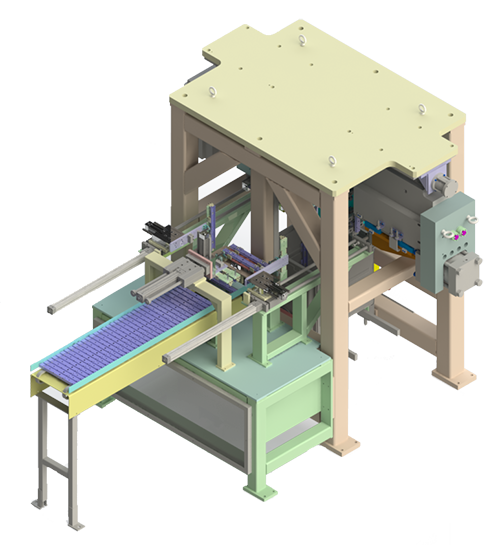

Tub Rail Assembly Machine

The purpose of this machine is to rivet drawer slide rails to the sides of a dishwasher tub

Key components used:

- Silent chain conveyor

- BTM Tog-L-Loc joining system

- Parker and PHD pneumatic cylinders and slide assemblies

- Piab vacuum products

Simplified Sequence of Operation:

- Operator manually loads rails onto silent chain conveyor

- Tub comes into station and hits retractable stop

- Conveyor transports rails to meter/stop that separates rails to 3” centers

- Overhead pick and place with vacuum tooling picks two rails off of conveyor and places them onto flip up tooling nest

- Flip up nest presents rails vertically to second pick and place

- Pick and place with vacuum tooling picks individual rails from flip up nests and places them into BTM Tog-L-Loc tooling

- Tub gets pumped up to stationary overhead locating tooling

- BTM unit cycles and joins rail to tub

- Tub lowers back onto conveyor